Full repair guide of LCD screen failure

LCD screen repair, bad LCD panel analysis, and solution

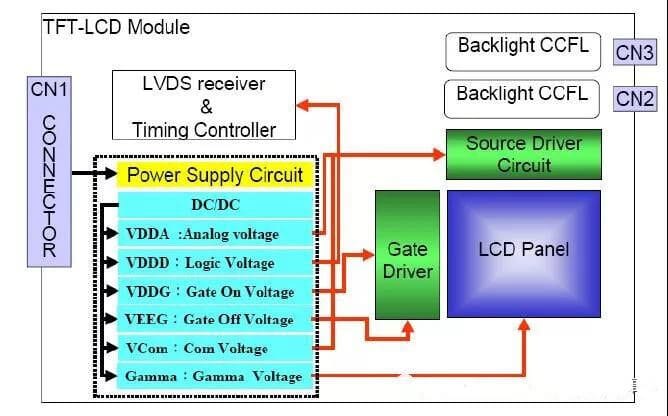

Working principle diagram of the LCD module

Definition

Vin: PWB input voltage (12V)

VDD: ASIC, source IC, gate IC driving power (3.3v)

VGH: TFT component switching voltage (~30V)

VGL: TFT component turn-off voltage (~ -6v)

VAA: step control voltage (~17V)

VCOM: liquid crystal reversal reference voltage (~7V)

No picture after Vin, VDD and VAA malfunction

Abnormal screen or slow screen switching after VGH and VGL failure

After the failure of Vcom, the picture will be weak or flickering

LCD fault(Liquid crystal fault)

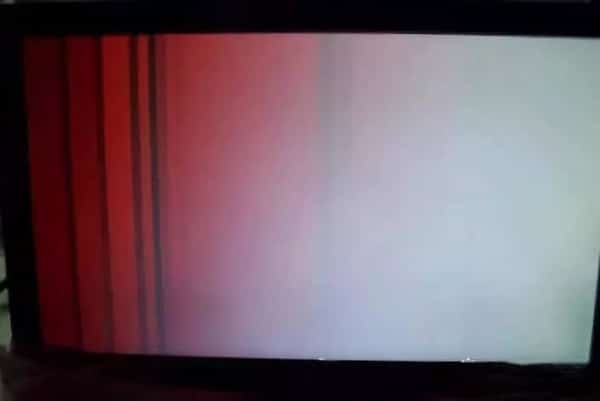

1. Picture color loss

Phenomenon: the picture is lack of color, or there are R/G/B color stripes under the step picture

| Possible Causes | Repair proposal |

Note

|

| Bad LVDS conn. | Replace LVDS connector | |

| Missing/burned RX resistor | Replace RX resistor | |

|

ASIC NG

|

Replace ASIC

|

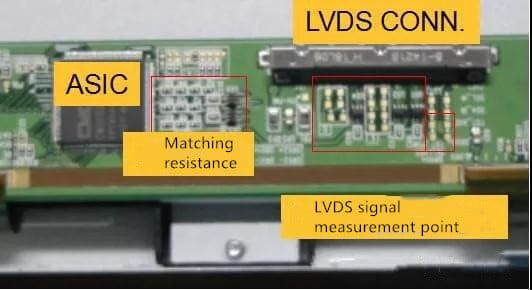

Analysis and solution:

1. #Confirm whether LVDS matching resistance is intact in appearance.

2. #Confirm whether the LVDS connector is OK or not. If the picture changed after pressing LVDS cable lightly, then something wrong with LVDS conn.

3. #If all the above is OK, measure the LVDS voltage value. Under normal conditions, the LVDS signal’s RX+/ RX-voltage value is about 1.2v, and RX+/ RX-difference value is about 200mV. At the same time, the resistance of the LVDS signal to ground and the resistance between the LVDS signal pairs can be measured (100 ohms). If there is an exception to these values, try replacing the ASIC.

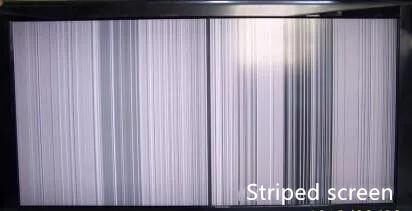

2. Striped screen

Phenomenon: full-screen vertical stripes (not gradient stripes) appear on the LCD display. In most cases, the display cannot be switched.

| Possible Causes | How to Repair |

Note

|

|

ASIC NG

|

Replace ASIC

|

No EIO signal

|

|

COF

|

COF replacement (LCD bonding&pressing equipment required)

|

COF VAA short to GND |

|

COF damaged(S/G)

|

Check COF appearance first

|

|

| COF comes loose | ||

|

PWM-IC NG

|

Replace PWM-IC

|

VAA short to GND |

| Other components NG |

Components associated with VAA have less chance of NG

|

Analysis and solution:

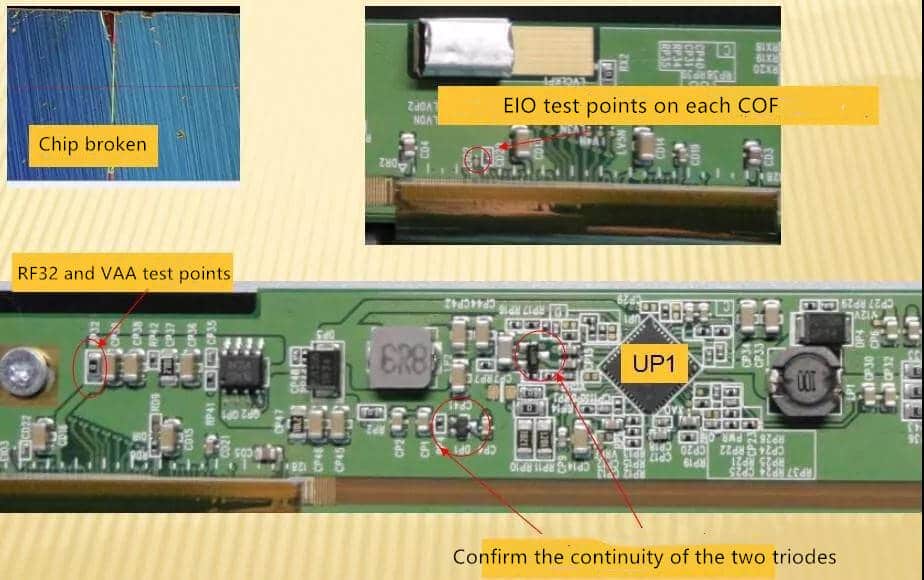

1. #Confirm whether the COF on side X is hot compared with the normal temperature, whether there is fracture or wear crack, and whether the COF is burnt.

2. #Confirm whether the VAA is normal (normally about 17V). If abnormal, disconnect the RP32 to confirm whether it is caused by DC/DC loop or X-side COF: disconnect RP32, if the VAA is normal, the COF is bad, CO must be changed; COF can be Disconnect one by one to determine which NG disconnects RP32, VAA NG, try to change UP1; at the same time, confirm whether the continuity of the surrounding triode is OK.

3. #Confirm whether EIO is OK (normal is 0.03v) and try to change ASIC if there is any abnormality.

4. #Determine whether the gate IC is OK. There is a signal test point on the back of COG-IC, and the green paint can be scraped for measurement confirmation; If there is a gate IC problem, which IC fault can be confirmed. The confirmation of gate IC fault is only for analysis when you are interested, and this method is not recommended.

3. Bad tone picture

Phenomenon: gradient fault occurs in the tone gradient screen or some gradient NG happens

| Possible Causes | How to Repair | Note |

|

Gamma-IC NG

|

Replace Gamma-IC

|

|

|

PWB line scratch (gamma line) |

Insulation tape on the scratch | If the line is broken, the PWB must be replaced.(LCD bonding&pressing equipment required) |

|

COF-IC NG

|

COF replacement (LCD bonding&pressing equipment required) |

Gamma-IC NG

|

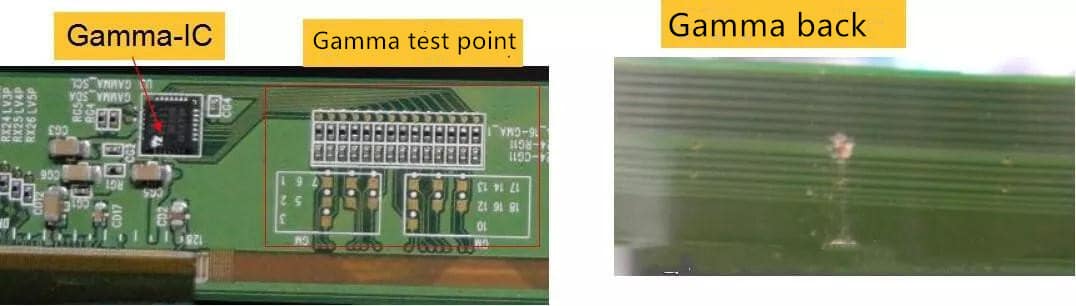

Analysis and solution:

1. #Measure GM1~GM14, the values are arranged from large to small. In general, a certain gamma value will be abnormal in the case of NG, then try to replace gamma-IC;

2. #See if there is any damage to the gamma line on the back of the PWB;

3. #If all of the above are OK, you should try to change the COF. You can disconnect the COF one by one to determine which IC is NG.

4. Half of the picture is abnormal

Phenomenon: The left and right screens are different

| Possible Causes | How to Repair | Note |

| Skew conductive foam shorts RSDS | Reattach or remove the conductive foam | |

|

ASIC NG

|

Replace ASIC

|

RSDS abnormal

|

| RSDS matching resistance NG | Replace RSDS resistor | |

| S-COF-IC poor bonding on the PWB side | COF replacement (LCD bonding&pressing equipment required) | |

|

S-COF-IC NG

|

COF driver RSDS NG

|

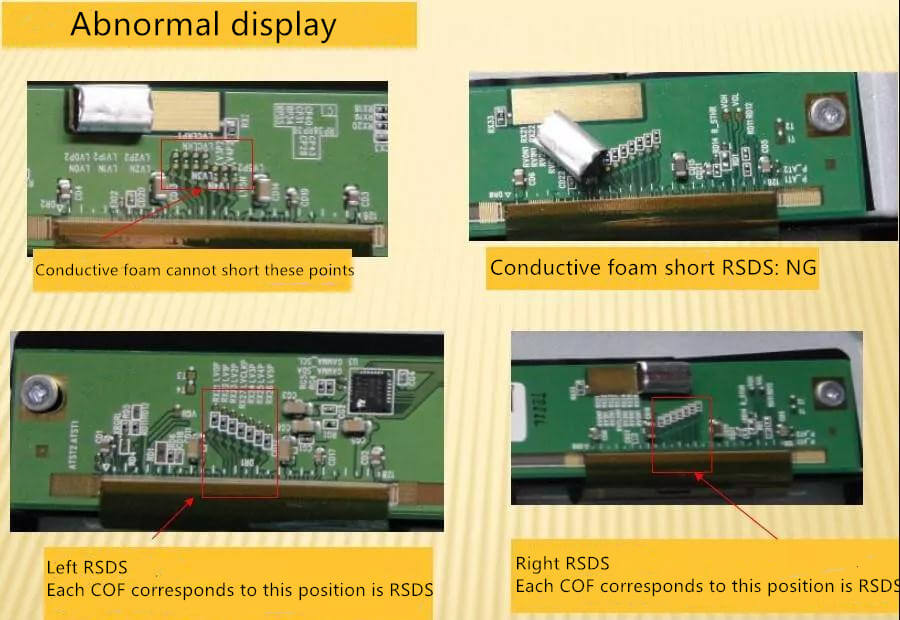

Analysis and solution:

Because the RSDS transmission basically adopts the double-channel mode, the analysis only needs to be carried out on the RSDS loop.

1. #Confirm whether the conductive foam is short-circuited RSDS

2. #Confirm whether X-COF has poor bonding

3. #Confirm whether the RSDS value is correct, normal RSDS is about 1.2v, and the signal difference is about 200mV; At the same time, we can confirm the resistance between RSDS signal (normal 100 or 50 ohms) and RSDS resistance to ground. If the voltage is NG, check if the ASIC and X-COF are hot.

Note: Confirm S1 RSDS if the left half screen is abnormal; confirm S8 RSDS if the right half screen is abnormal.

4. #In general, ASIC is mostly invalid, please try to replace it first;

5. #If it is still NG, remove the COF from the middle or last COF, and the RSDS voltage returns to normal.

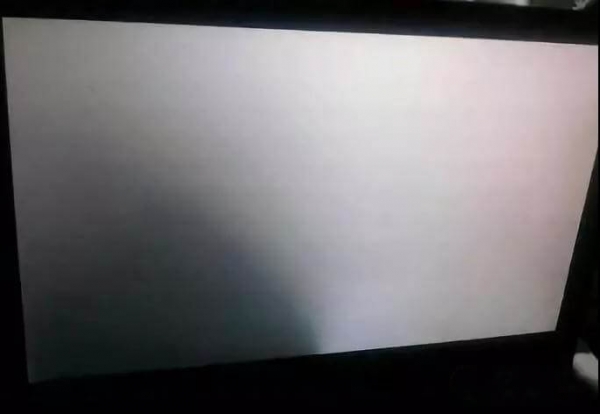

5. The panel color is whitish

Phenomenon: The screen can be switched normally, but the full-screen color is whitened/inaccurate.

| Possible Causes | How to Repair | Note | |

| Vcom value deviates | Vcom value is not adjusted | Reset VR knob | |

| VR knob is broken | Replace VR knob | ||

|

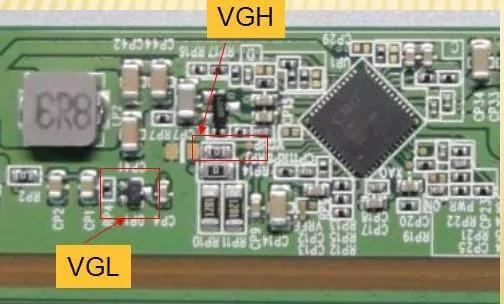

VGH/VGL NG

|

PWM-IC NG

|

Replace PWM-IC

|

|

|

Gate-IC NG

|

Gate-IC replacement (LCD bonding&pressing equipment required)

|

||

| Polarizer / CELL damaged |

To change the polarizer, a polarizer attaching machine is required

|

The degree of whitening of the picture changes with different viewing angles

|

|

Analysis and solution:

1. #Adjust the VR knob to see whether it can be adjusted and whether the screen performance changes. At the same time, confirm the VCOM value (about 7v), if NG, replace the VR knob.

2. #Confirm VGH/VGL voltage (about 30V VGH and -6v VGL), and confirm whether it is DC/DC loop NG or COF IC NG; The corresponding resistance of disconnected VGH and VGL can determine whether it is a DC/DC problem or a COF-IC problem. If it is DC/DC NG, try to replace UP1 or confirm whether the corresponding transistor is OK.

3. #If the whiteness changes significantly with the view Angle, and above 1&2 analysis is all OK, polarizer NG or CELL NG can be basically determined.

6. Slow screen switching

Phenomenon: the color of the LCD screen is dark. The picture can be switched, but the screen conversion is slow.

| Possible Causes | How to Repair | Note |

| WOA line is broken |

Replace PCB

|

PCB scrapped |

|

Gate-IC NG

|

Replace Gate-IC

|

|

| X1 Poor Looseness |

Replace X1

|

Analysis and solution:

1. #Confirm whether X1 is OK.

2. #Confirm whether WOA is disconnected when the CELL source goes to the gate side.

3. #Confirm whether the gate IC is OK. There is a signal test point on the back of COG IC, which can scrape the green paint for measurement confirmation; Or cut COF halfway from G3. If there is a gate-ic problem, which IC fault can be confirmed.

The confirmation of gate IC fault is only for analysis when interested, this method is not recommended.

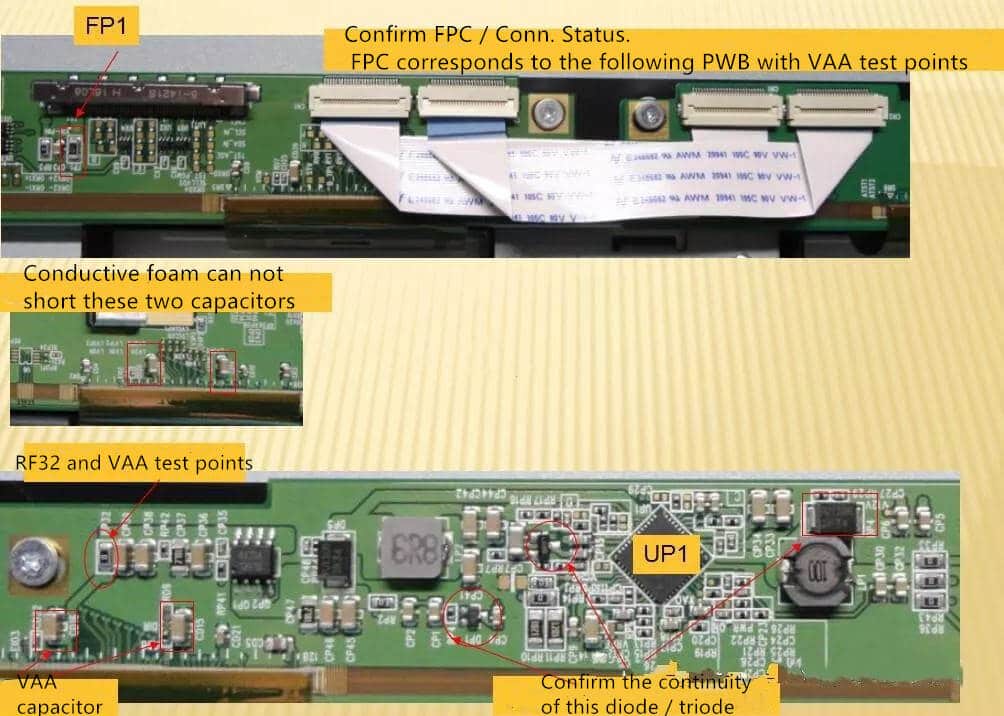

7. No display

Phenomenon: backlight is bright when the LCD panel is black

| Possible Causes | How to Repair | Note | |

|

LVDS connector NG

|

Wrong pin |

Replace conn.

|

|

| Poor connection | |||

|

F1 fuse open

|

Replace FP1

|

||

| Conductive foam short circuit element | Reattach or remove the conductive foam | Suitable for LCD module models with conductive foam | |

| FFC Goldfinger short circuit |

Replace FFC

|

Suitable for LCD models with L/R boards | |

|

ASIC NG

|

3.3V short to ground |

Replace ASIC

|

|

| No control signal | |||

|

DC/DC NG

(无VAA)

|

PWM-IC NG

|

Replace PWM-IC

|

|

|

X-COF NG

|

COF replacement (LCD bonding&pressing equipment required) | ||

| QP1 burned | Replace QP1 | ||

|

G-COF NG

|

COF replacement (LCD bonding&pressing equipment required) | ||

| Other components NG | Replace other components | ||

Analysis and solution:

1. #Confirm whether the conductive foam is skewed and short-circuit VAA capacitor ( LCD model with conductive foam)

2. #Confirm whether there is 12V input, if not, confirm whether the connector is OK, and confirm the resistance value of 12V voltage to earth; If conn. NG, change conn.; If 12V is short-circuited to the ground, disconnect FP1 to determine the short-circuiting circuit.

3. #Confirm whether FP1 is open; if open, replaces fuse. If the 12V accessory of this model has a reverse diode, confirm the continuity of the diode and check whether it is burnt.

4. #Confirm whether VAA is OK. For model with L/R board, remove FFC and confirm whether the screen can be switched or whether VAA is normal.

If VAA becomes normal:

A. Confirm whether the FFC has a pin short circuit and whether the FFC connector has a pin short circuit.

B. Confirm VAA resistance to ground at VAA test point of R plate (A short circuit usually occurs), disconnect the corresponding capacitance of the following 3 COF, and confirm VAA resistance to the ground again. If OK, replace the capacitor, if NG, replace COF. If VAA is still NG, confirm DC/DC loop as all models.

5. #Confirm whether the conductivity of the diode and triode in the DC/DC loop is OK, and change the corresponding components if NG.

6. #Disconnect RP32 to confirm VAA, if NG, try to change the PWM IC (in general, it will be good), if still NG, try to change the gamma-ic or corresponding to the VAA several large capacitances (in general, it is rare, this situation is generally accompanied by VAA to the ground short circuit).

7. #Disconnect RP32. If VAA is normal, measure the resistance to the ground at the other end of RP32. If still NG, you can change COF only.

8. #If VAA is normal at the beginning, there may be some problems with the control model (EIO can be measured). Try to change ASIC.

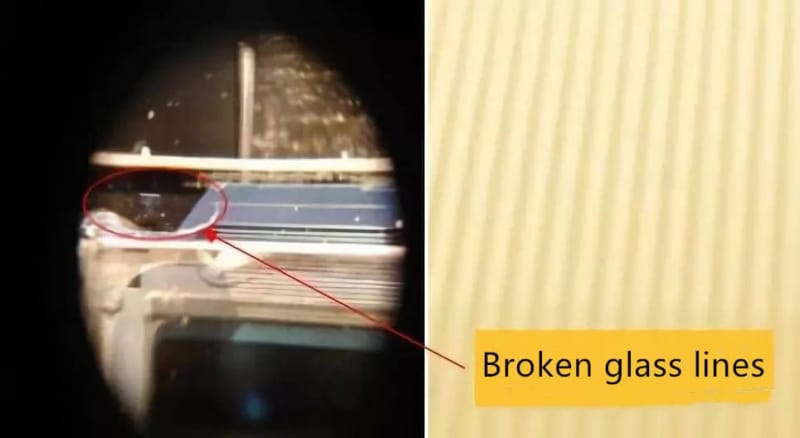

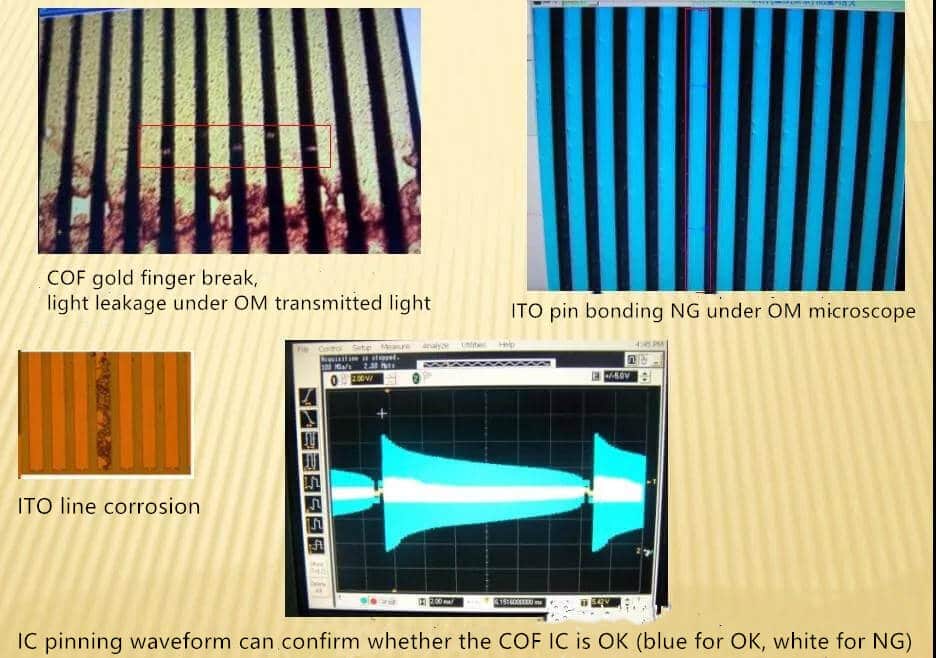

8. Display with vertical strips and lines

Phenomenon: vertical strips and lines appears in full screen

| Possible Causes | How to Repair | Note |

| COF poor bonding (PWB side) | COF replacement (LCD bonding&pressing equipment required) | |

| Poor COF |

Analysis and solution:

1. #Press COF and see if the display changes to determine if COF is OK.

2. #Confirm whether COF is hot or damaged. If COF needs to be replaced, LCD bonding&pressing equipment is required.

3. #Shaking module, if vertical lines disappear or reappear, then it can be judged that the possible cause is COF pin broken, and the crease should be found under the OM microscope.

4. #Press the LCD glass side of the panel, if the vertical lines disappear or reappear, it can be judged that the cause of poor contact, OM checking should be able to find the poor contact.

5. #If there is no display change in pressing, confirm whether ITO is damaged under the OM microscope, or pin signal waveform corresponding to needle COF.

Backlight failure

1. The screen does not light up

Phenomenon: the backlight is not lit, or it flashes off

| Possible Causes | How to Repair | Note |

| Lamp line is broken | Replace the lamp tubing | Depending on the backlight structure, there will be different results. The failure of the performance may be a point-off, or it may be a backlight with a dark band. |

| Broken high and low voltage plugs |

Replace plugs

|

|

| Lamp holder | Replace lamp/lamp holder | |

| Poor engagement of lamp holder | Replace lamp/lamp holder | |

| Lamp is broken | Replace the lamp | |

| Lamp welding failure | Resolder | |

Analysis and solution:

1. #Change the power board and inverter to determine if something wrong with the LCD panel itself.

2. #Check whether the light pipe and plug are OK, especially if the plug is burnt or yellow.

3. #Remove the backlight and confirm the status of the lamp holder and tube.

4. #The above disassembly judgment can basically solve the problems of point-off in the market. If you can’t tell the truth, you can directly change the lamp tube.

2. The dark band of the backlight

| Possible Causes | How to Repair | Note |

| Lamp line is broken | Reconnect / replace lamp tubing | Depending on the protection status of the power board, it may be a backlight with a dark band or it may be a point-off. |

| Plug disconnected / burned | Replace plugs | |

| Lamp is broken | Replace the lamp | |

| Lamp welding failure | Replace the lamp | |

3. Bad backlight / dark area

Phenomenon: The backlight is not lit or flashes off; or after the backlight is lit, the display appears dark along the edge of the front shell.

| Possible Causes | How to Repair | Note |

| The light bar is short-circuited to ground | Insulate or change the light bar | |

| Lightbar plug pin off | Change the light bar | |

| The light bar cable plug is not fully inserted into the conn. | Reinsert the light bar | |

| Lightbar conn. Pin is skewed | Change conn. Or re-insert the pin | |

| Light strip conn. Off | Reweld Conn. | If the PCB copper foil comes off, the light bar needs to be replaced |

| Bad light bar | Replace the light bar |

Analysis and solution:

1. #Change the power board first to determine whether the LCD panel itself is defective.

2. #look at the appearance of the light bar to determine whether there is a problem with the light bar.

3. #Disassemble the backlight, confirm whether there is a short circuit with broken skin on the lamp strip, whether the plug of the lamp strip is fully integrated with the socket, whether the pin is aslant/off, whether the connector is off, and whether the LED bead is black and injured.

4. #The fault of the product is basically caused by the above reasons. If the appearance is fault-free, the lamp bar can be crossed to confirm whether the phenomenon follows the lamp bar, or the voltage of the lamp bar and the conduction condition between the lamp beads can be measured.

The above is the full text of LCD screen failure repair guide, we hope it is helpful to you. If you need to buy LCD and find a reliable LCD supplier, we suggest you to read our other great blog – How to find a reliable LCD supplier.

If you have questions about LCD repair, please leave us a message in the comments section and we will respond as soon as possible.

Founded in 2014, VISLCD is a professional LCD supplier. We provide LCD modules, touch LCD and customized LCD in various sizes with stable quality and competitive price. Welcome to contact us for any LCD demand, thank you.

Hello. can one of these be repaired if torn?

Yes, if the flex cable can be replaced, it should be repairable.

Kalavad. Gujarat

what to check if the display is split in half vertically with one side producing a slightly darker color tones, and it’s not a backlight problem?

there are several factors and components you might want to check:

Cable and Connection;Graphics Card/Driver;T-Con Board;etc…

5.7 inch lcd display tft display some times working properly and suddenly giving trouble

There are many possibilities, such as power supply (voltage), firmware, backlight, EMI interference, and more…

how about a 7 inch car display that is half black. is there a problem in the circuit or replace the lcd screen

We think you need to check the flexible PCB of the LCD, if there is corrosion then the PCB needs to be repaired or replaced;

if the PCB is in good condition then we recommend just replacing the whole LCD.

Magnifique ce article

Thanks!

Thanks vеry interesting blog!

How about an LCD that is all white. No picture at all. Good article.

1. Check whether the power supply has DC voltage output.

2. Check whether there is a DC voltage output corresponding to the LCD glass at the screen line end of the LCD driver board

3. check whether the logic board or screen integrated board fuse has voltage.

4. check whether the screen 5 voltage is normal.

Can you repair electronic fault on LCD PCB for LG model LP156WF3-(SL)(B3) ?

yes

this article is a big help to understand how lcd panel works and fails,thank you.

You are welcome. We are glad it can help you:-)